Products

Each of these components plays a crucial role in ensuring that the painting or coating process is efficient, high-quality, and environmentally compliant. If you need more detailed information about any specific part, feel free to ask!

PRETREATMENT EQUIPMENT

PAINT APPLICATION & ROBOTS

Paint application equipment and robots are used to apply paint or coatings to the surfaces of materials. Robots are frequently employed for their precision and consistency in applying coatings, especially in high-volume production environments. They handle tasks such as spraying paint, applying primer, and applying other coating materials.

PAINT BOOTH & AIR-CONDITIONING SYSTEM

A paint booth is a controlled environment designed for the painting process. It manages overspray, contains fumes, and maintains cleanliness. The air-conditioning system within the paint booth regulates temperature and humidity, ensuring optimal conditions for paint adhesion and drying without defects.

CONVEYORS

Conveyors transport materials through various stages of the painting or coating process. They ensure smooth movement of items from one stage to another, such as from pretreatment to the paint booth and then to the drying ovens. Automated conveyors are crucial for maintaining efficiency and consistency.

PARKER LEAPS

Parker LEAPS is a tool designed to enhance work efficiency by quantifying information related to production, quality, cost, and environmental factors. It provides intuitive insights into equipment conditions and issues. Utilizing a secure cloud network, it allows real-time monitoring of equipment information via smart devices or tablets, even remotely. Additionally, it enables efficient preventive maintenance based on collected inspection data and maintenance history.

E-COAT EQUIPMENT

E-Coat, or electrophoretic coating, is a paint application process where an electric current deposits a coating onto a conductive surface. E-Coat equipment typically includes a bath where the parts are submerged, electrodes for the electrical current, and systems for handling and managing the coating solution.

IONICS

Parker Ionics delivers advanced powder coating technology and exceptional customer support. Their focus is on making high-tech powder coating solutions and educational resources accessible to painters of all business sizes.

OVENS

Parker Engineering offers a variety of ovens with different hot air discharge methods, heating systems (direct, indirect, or one-burner systems with incinerators), and exhaust abatement systems (TO or RTO). They also provide various tunnel configurations (camelback, flat, etc.), allowing for optimized systems tailored to your budget, environmental regulations, and building restrictions.

WASTE WATER TREATMENT

Wastewater treatment systems manage and process the wastewater generated during the painting or coating process. This includes filtering, neutralizing, and recycling the water to minimize environmental impact and comply with regulations. The system ensures that contaminants are removed before the water is either released or reused.

Products

Each of these components plays a crucial role in ensuring that the painting or coating process is efficient, high-quality, and environmentally compliant. If you need more detailed information about any specific part, feel free to ask!

PRETREATMENT EQUIPMENT

Pretreatment equipment is used to prepare the surface of a material before it undergoes the painting or coating process. This preparation often involves cleaning, degreasing, and sometimes applying a chemical treatment to ensure good adhesion of the paint or coating. Common pretreatment methods include acid baths, rinsing, and abrasive blasting.

PAINT APPLICATION & ROBOTS

Paint application equipment and robots are used to apply paint or coatings to the surfaces of materials. Robots are frequently employed for their precision and consistency in applying coatings, especially in high-volume production environments. They handle tasks such as spraying paint, applying primer, and applying other coating materials.

PAINT BOOTH & AIR-CONDITIONING SYSTEM

A paint booth is a controlled environment designed for the painting process. It manages overspray, contains fumes, and maintains cleanliness. The air-conditioning system within the paint booth regulates temperature and humidity, ensuring optimal conditions for paint adhesion and drying without defects.

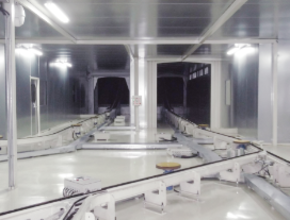

CONVEYORS

Conveyors transport materials through various stages of the painting or coating process. They ensure smooth movement of items from one stage to another, such as from pretreatment to the paint booth and then to the drying ovens. Automated conveyors are crucial for maintaining efficiency and consistency.

PARKER LEAPS

Parker LEAPS is a tool designed to enhance work efficiency by quantifying information related to production, quality, cost, and environmental factors. It provides intuitive insights into equipment conditions and issues. Utilizing a secure cloud network, it allows real-time monitoring of equipment information via smart devices or tablets, even remotely. Additionally, it enables efficient preventive maintenance based on collected inspection data and maintenance history.

E-COAT EQUIPMENT

E-Coat, or electrophoretic coating, is a paint application process where an electric current deposits a coating onto a conductive surface. E-Coat equipment typically includes a bath where the parts are submerged, electrodes for the electrical current, and systems for handling and managing the coating solution.

IONICS

Parker Ionics delivers advanced powder coating technology and exceptional customer support. Their focus is on making high-tech powder coating solutions and educational resources accessible to painters of all business sizes.

OVENS

Parker Engineering offers a variety of ovens with different hot air discharge methods, heating systems (direct, indirect, or one-burner systems with incinerators), and exhaust abatement systems (TO or RTO). They also provide various tunnel configurations (camelback, flat, etc.), allowing for optimized systems tailored to your budget, environmental regulations, and building restrictions.

WASTE WATER TREATMENT

Wastewater treatment systems manage and process the wastewater generated during the painting or coating process. This includes filtering, neutralizing, and recycling the water to minimize environmental impact and comply with regulations. The system ensures that contaminants are removed before the water is either released or reused.

STANDARD PRODUCTS

Standard products refer to various paint or coating products that adhere to established industry standards. These include primers, topcoats, and specialty coatings formulated to meet specific performance and quality requirements.

Get in touch with us

Discover how Parker Engineering can help you achieve your project goals with precision and innovation. Our team of experienced engineers is dedicated to delivering customized solutions that meet your unique needs. Whether you’re tackling a complex infrastructure project or seeking cutting-edge technological solutions, we have the expertise to turn your ideas into successful outcomes. Start your journey with us today and experience the difference that professional engineering can make.